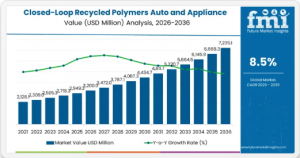

Closed-Loop Recycled Polymers Auto and Appliance Components Market Projected to Reach USD 7,235 Million by 2036

Global demand for recycled polymers in automotive & appliance components grows as manufacturers adopt circular systems to meet sustainability & compliance goals

NEWARK, DE, UNITED STATES, January 20, 2026 /EINPresswire.com/ -- The Closed-Loop Recycled Polymers Auto and Appliance Components Market is expected to experience sustained expansion through 2036 as automotive and appliance manufacturers accelerate adoption of circular manufacturing models designed to reduce waste, stabilize material supply, and meet evolving regulatory requirements. Industry analysis indicates the market is projected to grow from USD 3,200.0 million in 2026 to approximately USD 7,235.0 million by 2036, reflecting a compound annual growth rate (CAGR) of 8.5%.

Market Overview: Who, What, When, Where, Why, and How

Who

The market is driven by automotive original equipment manufacturers, appliance producers, polymer recyclers, and tier-one component suppliers implementing closed-loop material systems. Key participants across the value chain include global automotive suppliers, materials engineering firms, and vertically integrated manufacturers focused on sustainability-led product design.

What

Closed-loop recycled polymers are materials recovered from post-consumer and post-industrial plastic waste and reprocessed for reuse in automotive and appliance components. Unlike open-loop recycling, these systems maintain material traceability and performance consistency, enabling recycled polymers to be repeatedly used in similar applications without compromising functional or aesthetic requirements.

When

The forecast period spans 2026 to 2036, reflecting a decade of transformation in materials sourcing strategies as manufacturers align with long-term environmental, regulatory, and operational efficiency goals.

Where

Adoption is global, with strong momentum across major manufacturing hubs including China, Germany, the United States, the United Kingdom, Japan, and South Korea. These regions benefit from advanced recycling infrastructure, established automotive and appliance production bases, and regulatory frameworks that support circular economy initiatives.

Why

Market growth is primarily driven by tightening environmental regulations, extended producer responsibility requirements, and corporate sustainability commitments. Manufacturers are increasingly required to reduce reliance on virgin plastics, disclose recycled content levels, and demonstrate end-of-life material recovery pathways. Closed-loop recycled polymers directly address these pressures by supporting compliance while delivering cost and supply chain advantages.

How

Technological advancements in material sorting, polymer regeneration, and contamination control have enabled recycled polymers to meet stringent performance standards. OEM-led closed-loop programs and supplier-managed recycling systems are being integrated into production workflows, particularly for interior, trim, and structural components where material consistency is critical.

Market Context and Industry Significance

Circular Economy Integration

Closed-loop recycling plays a central role in the automotive and appliance industries’ shift from linear production models toward circular systems. By reintegrating recovered plastics into new components, manufacturers reduce landfill waste, lower carbon footprints, and improve long-term material security.

Regulatory Alignment and Risk Mitigation

Governments worldwide are enforcing stricter regulations on plastic waste, recycling rates, and product lifecycle accountability. Closed-loop systems help manufacturers mitigate regulatory risk by providing transparent, auditable recycling processes that align with environmental compliance requirements.

Application and Material Trends

Automotive interior components represent the largest application segment due to high-volume usage and suitability for recycled polymer integration. Polypropylene and thermoplastic olefin materials lead adoption due to their durability, recyclability, and compatibility with existing manufacturing processes. Appliance components increasingly incorporate closed-loop polymers to meet sustainability benchmarks without sacrificing product longevity.

Competitive and Strategic Implications

Corporate sustainability goals and investor scrutiny are driving long-term demand for closed-loop materials. Collaboration among OEMs, suppliers, and recycling technology providers is accelerating innovation, enabling scalable recycling systems and consistent material quality across global supply chains.

Future Outlook

The closed-loop recycled polymers market is expected to maintain strong growth through 2036 as sustainability becomes a core operational requirement rather than a discretionary initiative. Continued investment in recycling infrastructure, digital material tracking, and advanced polymer processing technologies is anticipated to further expand application potential across automotive electrification platforms and durable appliance manufacturing.

Request for Sample Report | Customize Report |purchase Full Report – https://www.futuremarketinsights.com/reports/sample/rep-gb-31578

Explore More Related Studies Published by FMI Research:

AKD Emulsifier Market https://www.futuremarketinsights.com/reports/akd-emulsifier-market

Rust Remover Market https://www.futuremarketinsights.com/reports/rust-remover-market

UK Plastomers Market https://www.futuremarketinsights.com/reports/united-kingdom-plastomers-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

rahul.singh@futuremarketinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.